The newly renovated Los Alamos National Laboratory is the only full-scale finishing facility in the Department of Energy.

Photo Credit: All photos courtesy of Los Alamos National Laboratory

A robust surface finishing capability is critical to Los Alamos National Laboratory’s nuclear security enterprise. For more than six decades, the Laboratory’s Sigma Complex has been home to a large, dedicated space for the performance of world-class surface science, supporting mission-essential parts production and manufacturing methods development.

Jamie Stull inspects gold-plated vanadium parts.

The Electrochemistry and Corrosion team at Los Alamos National Laboratory performs surface and interface characterization, coatings development, corrosion testing, and processing of highly diverse materials from the nanoscale to production scale. The results of their work range from one-off hardware to routine production of parts, and studies into material’s aging and lifetime behaviors for research and development, weapons, and space applications. Processes include the usual commercial solutions for nickel, gold, copper, and chromate, to give a few examples. They also include the very unusual, including custom coatings that incorporate nanoparticles, single layers of graphene, or materials that are not normally plated commercially, like rhenium. Substrates span everything from common to exotic materials, and even include things like flex-circuits.

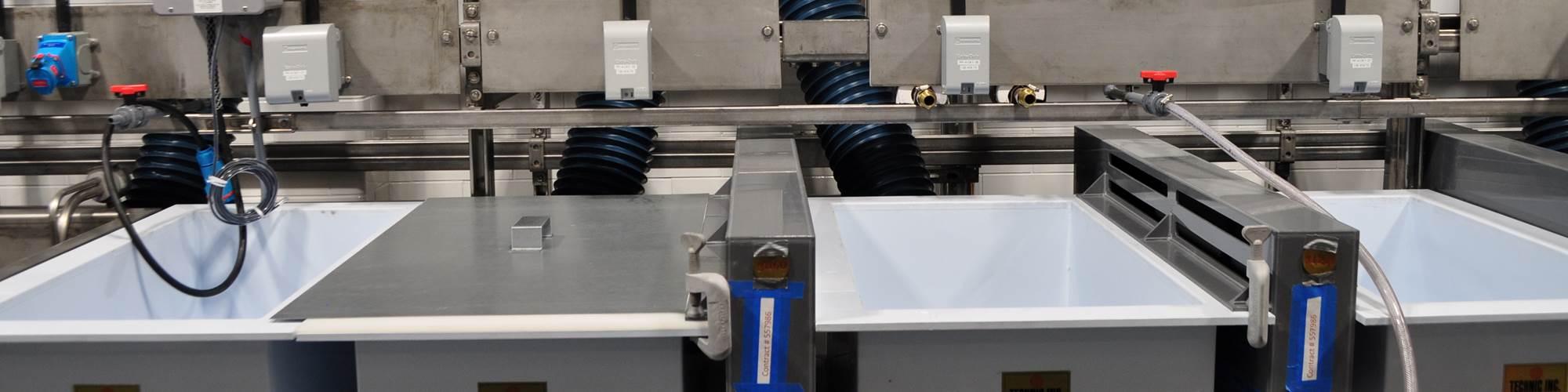

The shop space is home to an industrial cleaning, plating, and anodizing capability that looks a lot like many other commercial finishing shops, but there are some differences. An obvious difference is that the process tanks are fairly small, with 50 to a few-hundred gallons being typical. The biggest distinguishing feature is the ability to process exotic materials like uranium and beryllium. The Sigma Complex is dedicated to the research and development of manufacturing methods, with in-house operations including casting, machining, forming, and welding. The dynamic nature of research needs at Los Alamos include the processing of many materials, including nearly everything on the periodic table up to uranium. The finishing shop exists to support this research. A cleaning operation immediately before welding, forming, or other processing may be needed, and doing so in-house best meets this need. But it also enables so much more at Los Alamos, as it provides the ability to quickly produce research prototypes for the many mission needs across the Laboratory as a whole, which spans more than 47 square miles and employs approximately 13,500 people. For ideas that ultimately must be produced beyond the needs of research, developing production methods for unique processes is needed. Beyond the main finishing shop, the capability is complemented by other labs equipped to do beaker-scale work, scale-up, and analytical, as well as sample preparation, and characterization tools.

This photo from January 2019 shows the facility prior to renovation.

Years of use with few updates had left the surface finishing shop in disrepair, challenging the creativity of the Electrochemistry and Corrosion team members tasked with meeting current mission deliverables and preparing for new mission needs.

In an effort of careful coordination between R&D and operations staff, the shop has been completely rebuilt and is back better than ever. It remains the only full-scale finishing facility in the Department of Energy, and is now world-class by any standard.

Driving this endeavor has been program needs for war-reserve production and critical space hardware, as well as hydrotest and a large variety of other research hardware.

After more than two years, the lab renovation is complete and ready to serve anyone at Los Alamos National Laboratory needing research for coating development, corrosion and interface effects, coatings on research hardware or anything else.

Although similar to commercial finishing shops, the unique materials processed at the Los Alamos shop were reason for extra caution during the renovation. In addition to all of the expected chemicals and materials in a commercial finishing shop (chromium, lead, etc.), the presence of radioactive and other toxic materials like beryllium made the renovation more complex. It also led to some unique operating characteristics, as even things such as rinse processes must be reevaluated due to the unique requirements for handling wastewater in a radiological facility.

Faced with often daunting infrastructure challenges, the 50-member construction crew became adept at overcoming unexpected facility conditions as the lab was remade with new utilities and equipment. Their approach — which integrated the efforts of construction maintenance staff with facility operations staff, program management and industrial hygiene and radiation protection professionals — resulted in the removal of thousands of gallons and pounds of hazardous waste.

The lab was stripped of everything to enable a complete decontamination, ensuring that all the new equipment could be installed in an assuredly clean space. New ventilation, electrical, and other utilities were installed to support new process equipment.

The Sigma Electrochemistry and Corrosion Team at Los Alamos National Laboratory includes (from left) Dan Hooks, Jamie Stull, Randy Edwards, Courtney Clark, Don Johnson, Allen Gresham, Mary O’Brien, Tim Gorey, and Brad Carpenter.

Meanwhile, all of the usual finishing work still needed to be done. To meet ongoing project deliverables, the 25-member Electrochemistry and Corrosion team adapted to the circumstances. Working seven days a week in rotation, due to the pandemic and to provide daily attention for some parts, in conditions that sometimes included no heat, no light, or running water, team members produced to-specification satellite components, thousands of detonator cables, and other essential components for Laboratory missions.

Installation of a new floor for the facility was completed by the GOAD Company in July 2020.

Throughout, there were very tightly integrated interactions between construction, scientific staff, and vendors to choreograph delivery of mission needs, construction and vendor installations. To give an example, because of the Covid pandemic, the construction and scientific crews hosted an installation team from the GOAD Company (Independence, Mo.) over the fourth of July weekend to install the new floor.

In short, the technical team delivered in imperfect circumstances, and the construction team pulled off an extraordinarily difficult renovation.

Allen Gresham racks coupons for chromate coating and subsequent salt-spray quality testing.

Reaching out to the finishing community has been important to the Los Alamos team as it has grown. The national laboratories have a long history of involvement with the surface finishing community. The Los Alamos staff continues to engage with this community, with technical contributions at the National Association for Surface Finishing SUR/FIN conferences and participation in training and certification through the society. This interaction was important to the renovation. The renovation was “clean sheet,” and everything had to be sourced, from ventilation, to process tanks, to power supplies and process equipment. Going through this design, sourcing, and setup process was a once-in-a-lifetime experience for the staff. The connection to industry is also important for other reasons. Most in the industry know that the skillset of the finishing community is quite unique, and the ability to talk through issues and challenges with others in the field is critical. Finally, one of the goals of the manufacturing research mission is to connect with those in the industry to take the baton when the time comes to take something from research to production.

Leveraging the surface finishing shop’s new and improved capabilities, team members are already thrilled by what the new shop is capable of. One example is treatment of the surfaces of additively manufactured metal surfaces. Even though these new technologies enable “printing” any shape, the expectation is that the parts can still meet surface specifications. The finishing industry hasn’t seen anything like these surfaces, so the team is developing new methods to process them to meet roughness and corrosion requirements. Taking it from the beaker to industrial practice is made possible by the new Los Alamos National Laboratory Electrochemistry and Corrosion finishing shop.

Daniel Hooks is the team leader for Electrochemistry and Corrosion in the Sigma facility at Los Alamos National Laboratory.

Related Content

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreCalifornia Public Hearing to Decide Fate of Hex Chrome Plating and Anodizing

Metal Finishing Association of California urges all members of the metal finishing community to submit comments prior to the hearing.

Read MoreUnderstanding and Managing White Spots on Anodized Aluminum

Having trouble with spotting defects when anodizing? Taj Patel of Techevon LLC offers a helpful overview of the various causes of white spots and potential solutions.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreMasking Solutions for Medical Applications

According to Custom Fabricating and Supplies, a cleanroom is ideal for converting, die cutting, laminating, slitting, packaging and assembly of medical-grade products.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More