SRG Global Celebrates New World HQ with Opening Ceremony

The new facility, which opened this summer, is a 51,000-square-foot building currently housing more than 250 employees.

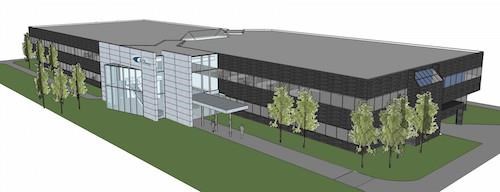

SRG Global held an opening ceremony Sept. 19 at its new world headquarters in Troy, Michigan for employees, representatives from Guardian Industries and human resource leaders representing the company’s plants around the world.

The new facility, which opened this summer, was built with the focus of future growth and attracting top talent. The 51,000-square-foot building currently houses more than 250 employees.

“Our vision is to be a trusted global partner, to continue to grow and provide engineering solutions that create superior value for our customers and society,” Dave Prater, President and CEO of SRG Global said while addressing event attendees. “This new facility is another step toward upholding that vision and serves as a flagship for our company.”

As a leading global manufacturer, SRG Global is well-known as a Tier 1 interior and exterior trim supplier, providing solutions that add both style and function for the automotive and commercial truck industries.

The new headquarters was designed to encourage both individual development of each employee and also collaboration between departments to foster innovation and to inspire ideas in a teamwork atmosphere. The facility features an open layout with an atrium and central staircases, natural lighting and several common areas.

For information, visit srgglobal.com.

Related Content

-

Nanotechnology Start-up Develops Gold Plating Replacement

Ag-Nano System LLC introduces a new method of electroplating based on golden silver nanoparticles aimed at replacing gold plating used in electrical circuits.

-

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

-

Products Finishing Reveals 2023 Qualifying Top Shops

Each year PF conducts its Top Shops Benchmarking Survey, offering shops a tool to better understand their overall performance in the industry. The program also recognizes shops that meet a set of criteria to qualify as Top Shops.