Ultrafiltration (UF) is a critical technology for the electrocoating process because it closes the mass balance of the process while producing rinse waters from the electrocoat paint bath, often resulting in 95 percent or higher transfer efficiencies with no net water addition.

UF can also be used to recover paint solids from deionized (DI) rinse water, thereby reducing the amount of paint wasted and lessening the burden on wastewater treatment facilities.

Koch Membrane Systems, Inc., with a worldwide installed base approaching 20,000 systems, says its ROGA cellulose acetate membranes are designed for high organic fouling environments and widely used for applications where chlorine is needed on a continuous basis. They can be used in new or existing systems, and are ideal for high-rejection processes where oxidizing agents are a concern, says Dr. Mark Rizzone, market manager in the company’s Industrial and Life Sciences Group.

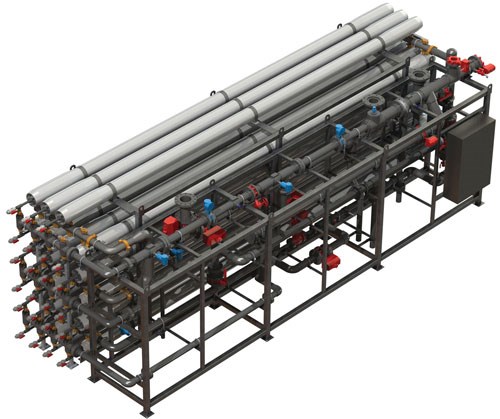

“Our pre-engineered, packaged water treatment systems using reverse osmosis (RO) and nanofiltration (NF) technology offer optimum water treatment for brackish and seawater applications within a compact, skid-mounted package,” he says.

Rizzone says the standard pre-engineered RO packaged plants can be used with all equipment, and the modular, reduced-scope Vessel Control Block system is suited to larger projects and operators who prefer to provide axial equipment.

Ultrafiltration is a pressure-driven process that removes emulsified oils, metal hydroxides, colloids, emulsions, dispersed material, suspended solids, and other large molecular weight materials from water and other solutions. UF membranes are characterized by their molecular weight cut-off.

“Electrocoat paint is a colloidal dispersion of pigment and resin in water with solubilizer, salts and solvents,” Rizzone says. “In ultrafiltration of electrocoat paint, the pigment and high-molecular-weight resin are rejected by the membrane and the water. Low-molecular-weight resin, solubilizer, dissolved salts and solvents pass through the membrane as UF permeate. The UF permeate can be further filtered to generate a higher quality closed-loop rinse water.”

So the challenge for most electrocoaters is to treat UF permeate to reduce DI water consumption, increase paint solids recovery, and decrease water and wastewater treatment in electrocoat paint process applications.

According to Rizzone, the solution often can be found in reverse osmosis, which can be used to remove low-molecular-weight resin and dissolved salts from electrocoat paint ultrafiltrate, thereby reducing the consumption of DI water and generating less wastewater.

Koch says its ROGA cellulose acetate RO elements provide a successful solution for processing UF system permeate from electrocoat processes. ROGA membranes have shown stable permeate rates compared with other types of RO membranes when operated on cathodic ultrafilter permeate, Rizzone says, leading to less frequent membrane cleanings and better acceptance of RO technology for this application by electrocoat end-users.

“RO for cathodic electrocoat ultrafiltrate can be used in both new and existing plants and may potentially improve quality and reduce defects,” he says. According to Rizzone, the list of customers using Koch membranes in their electrocoating processes includes leading global manufacturers producing automobiles, appliances, metal furniture, lawn and garden equipment, and more.

For example, Rizzone says that several years ago, a UF/RO system was installed at an automotive assembly plant in Texas to process electrocoat paint. The paint type was an unleaded, gray cathodic epoxy, and typical paint characteristics were total solids at 20.5 percent, a pH of 6, conductivity at 1,500 to 1,600 micromhos, and temperature at 90°F. The ultrafilters used in this case were 10-inch diameter KPAK spirals and were designed to generate 24 gal/min of UF permeate. The ultrafiltrate consisted of 0.6 percent total solids and was sent to a UF permeate holding tank.

The RO system used 8-inch diameter cellulose acetate RO spirals and was designed to generate 4 gal/min of RO permeate. The RO concentrate was returned to the UF permeate tank which overflowed to the last re-circulated spray rinse in the closed-loop rinse system. The RO permeate was sent to an RO permeate storage tank from which it was pumped to a spray halo as the last rinse in the closed-loop rinse system.

Rizzone says that one year of operating data showed that both the UF and RO systems demonstrated very stable permeate rates. During this time period, neither system needed cleaning, and the inlet operating pressures averaged 45 psi for the UF system and ranged between 80 and 100 psi for the RO system. The RO permeate conductivity was approximately 60 micromhos, while the RO feed conductivity ranged from 1,000 to 1,250 micromhos. The RO permeate pH ranged from 3 to 5, while the RO feed pH ranged from 5 to 6.

As another example, an RO system was installed at an automotive assembly plant in Canada with the primary objective to reduce the amount of DI water usage in the electrocoat rinse following the closed loop while maintaining or improving vehicle paint quality (i.e., same or less defects).

The project included increasing the existing UF permeate rate and installing an RO system on the electrocoat UF permeate to reduce total solids upstream in the closed-loop rinse with rinse system modifications.

Rizzone says the ultrafilter capacity was increased by adding large-area, 10-inch diameter potted UF spirals to the existing 8-inch diameter spiral system, and using available excess pumping capacity. The ultrafilter permeate rate was increased from 23 gal/min to 30 gal/min. The RO unit used 8-inch diameter cellulose acetate membrane elements and was sized to generate 10 gal/min of RO permeate.

The RO permeate was sent directly to a spray halo to serve as the last rinse in the closed loop, and the RO concentrate was sent to the UF permeate holding tank. A pump sent the UF permeate from the holding tank to a spray rinse just ahead of the RO permeate spray rinse.

Rizzone says the reduction in DI water usage due to RO system implementation, increase in UF permeate rate, and modifications to the closed-loop and DI rinse systems was estimated at 67 percent. An annual cost savings of nearly $250,000 was estimated based on decreased DI water use, decreased water treatment, decreased wastewater treatment, increased paint recovery and decreased biocide additions. The project has an estimated payback of less than two years. n