research

Direct Metallization for Plating on Plastics

A new combination of copper immersion and autocatalytic copper-(I)-oxide deposition enables lower palladium concentrations in the activator bath, though the amount of copper deposited on the plastic surface can be up to ten times higher compared to its predecessor processes.

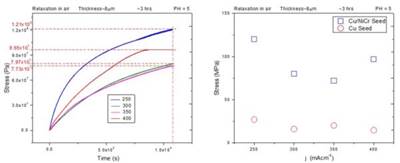

Read MoreCrack Formation during Electrodeposition and Post-deposition Aging of Thin Film Coatings - 6th Quarterly Report

This NASF-AESF Foundation research project report covers the sixth quarter of project work (April-June 2017) on this AESF Foundation Research project at the University of Houston. The objective of the work is to study fundamental and practical aspects of crack formation in electrodeposited thin films.

Read MoreDefects in Hard Chromium Deposits Part II: Detection, Prevention and Repair

Most defects in various hard chromium deposits arise from defects in the basis metal. These defects may be in the original metal surface or may be caused by preplate finishing. Homogeneous hard chromium deposits can be produced only by eliminating these defects. The final segment of this article describes visual and provocative methods of detecting defects. Also discussed are prevention techniques and repair operations.

Read MoreDefects in Hard Chromium Deposits Part I: Causes and Cures

The causes of and remedies for defects in hard chromium deposits are explored in the first of this two-part P&SF article from 1984. Photomicrographs and SEM (scanning electron microscope) photographs will illustrate that most defects in various hard chromium deposits arise from defects in the basis metal. These defects may be in the original metal surface or may be caused by preplate finishing. Homogeneous hard chromium deposits can be produced only by eliminating these defects. Practical suggestions and procedures will be given.

Read MoreCan Electroplated Fe-C be an Environmentally Friendly Alternative to Hard Chromium and DLC Coatings?

Electroplated FeC is an efficient surface treatment based on non-aggressive chemicals with a deposition rate of ~20 μm/h at a process temperature of 50°C. The FeC coating is carbide-free and temperature stable up to ~250°C with a hardness of 750 HV, which is comparable to frequently applied hardened steels. The FeC coating has reasonable friction properties and have high affinity towards lubricants because of incorporated amorphous carbon. Hence, for certain applications, the FeC coating might be an interesting wear-protective alternative to hard chromium and to PVD-deposited low-friction diamond-like carbon coatings (DLC’s), which are rather difficult and costly to deposit on larger items.

Read MoreSulfuric / Organic Electrolytes and Total Quality Improvement (TQI) for Present / Future Anodizing Requirements

After the last 12 years of developmental improvements and successful operation in production and selective brush anodizing, we present formulations for the new revised three-part organic acid blend. This ionic active blend detailed here can benefit all sulfuric anodize electrolytes to meet today's more demanding quality, specifications and production requirements.

Read MoreDon’t Believe Everything You Hear - The 22nd William Blum Lecture

This article is a re-publication of the 22nd William Blum Lecture, presented at the 68th AES Annual Convention in Boston, Massachusetts, on June 29, 1981.

Read MoreProduction Schedule Driven Automated Energy Management

Surface finishing line process automation systems are normally designed to optimize production throughput and assure compliance with operating parameters such as time-in-tank. The basic elements of automated energy management on process lines are control of energy consumption in active, standby and inactive states, primarily by ventilation, heating and cooling, agitation and filtration. This paper presents a case study of the new process control model.

Read MoreThe Nature, Cause and Effect of Porosity in Electrodeposits: A Microscopic Examination of Nickel-Chromium Coatings after Atmospheric Corrosion

This paper is one of seven reports constituting AES Research Project #13, dealing with the nature, cause and effect of porosity in electrodeposits, performed at the then-National Bureau of Standards, in Gaithersburg, Maryland. It was one of several seminal articles produced through AES Research during the height of the automotive/decorative segment of the surface finishing industry in the 1950s and 60s.

Read MoreCrack Formation during Electrodeposition and Post-deposition Aging of Thin Film Coatings - 4th Quarterly Report

Fourth Quarterly Report - AESF Research Project #R-118. This NASF-AESF Foundation research project report covers the fourth quarter of project work (October-December 2016).

Read More